The Innometal family, which has been in the production adventure for generations, has met the metal in its name as far back as the days when our grandfathers' profession, hot blacksmithing, was done with anvil and hammer, and continues this accumulation with innovative approaches and today's technology. We continue our role of being the leading production mind in the region, which our partners have realized in different formations, by updating it under the roof of Innometal. Our family continued to establish and operate water mills in the region until the 1950s. Subsequently, the establishment and operation of diesel flour mills, the manufacture of axles for ox carts, and the production of hand and horse-powered water pumps continued.

To satisfy our customers by using the most up-to-date technologies in production and process management.

To be one of the companies with the leading production capacity and quality in our sector.

To increase the satisfaction of our customers with our products and services in accordance with customer demands and expectations, taking into account all legal obligations and relevant standards, To continuously improve its effectiveness by developing the Quality Management System; to fulfill all applicable requirements, To strengthen our infrastructure by giving importance to technology and human investment; to ensure the development of our personnel through continuous training, To increase our productivity by working in mutual cooperation and trust by ensuring the participation of all employees, suppliers and customers with teamwork, communication, common problem solving and trust, To become the market leader by increasing our market share and competitiveness in the sector.

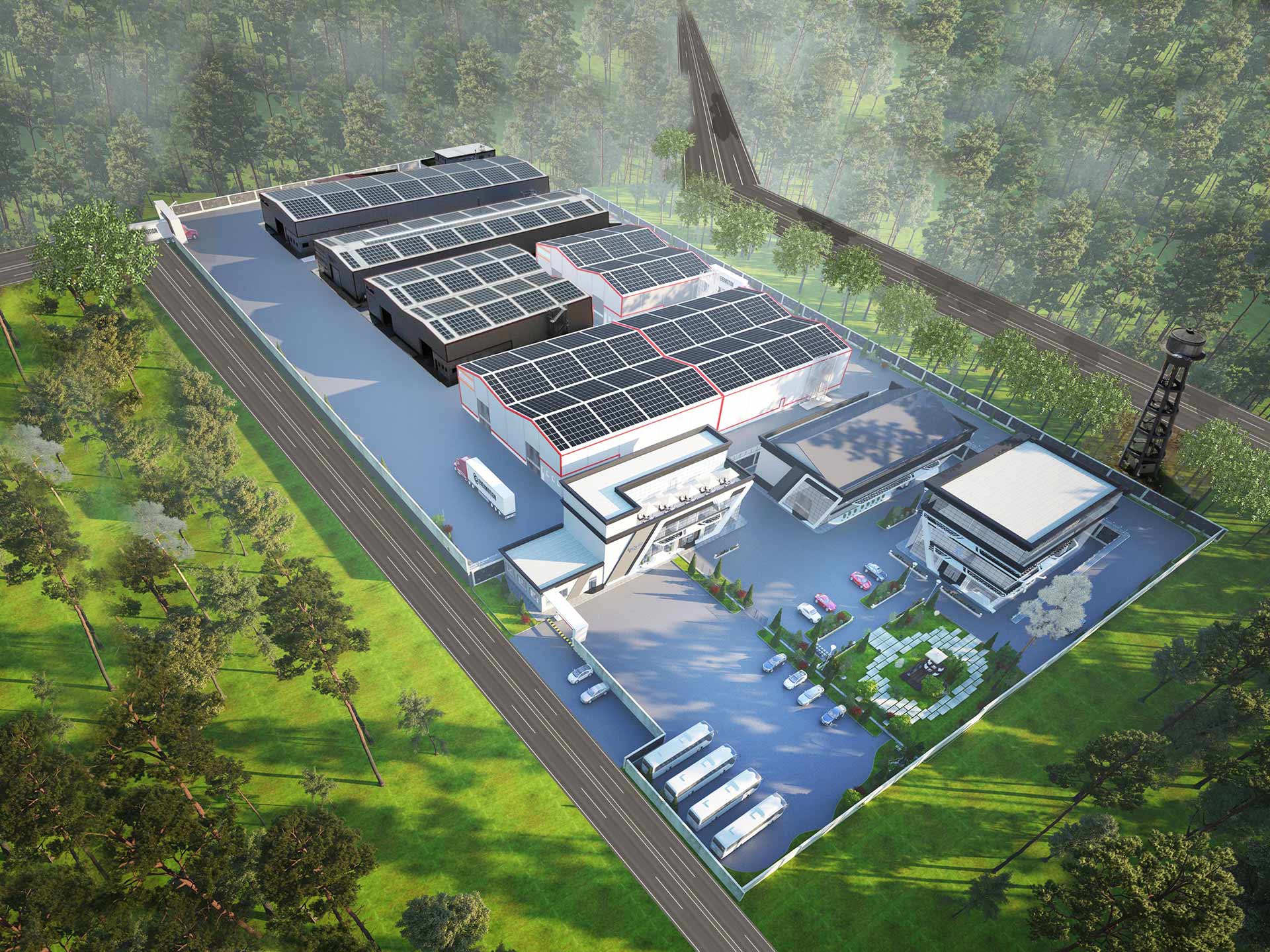

After the 1960s, our activities of maintenance-repair and spare parts manufacturing of gasoline and diesel water engines, maintenance-repair and spare parts manufacturing of motor vehicles, as well as spare parts manufacturing, lathe and welding work for the shotgun sector, which is common in the environment, continued until the 1990s. Afterwards, our family subsidiary company made manufacturing in different branches of the metal industry in our factories in Huğlu and also made manufacturing in different branches such as various parts for the defense industry, various parts for the medical sector, engine crank manufacturing and shotguns in our subsidiary companies. For this reason, it has manufacturing experience with different materials from aluminum, titanium, non-ferrous metals to high quality steels. After 2016, a different structuring was made and manufacturing activities started in an area of 34,000 square meters in Beyşehir Organized Industrial Zone. With 6,600 square meters completed and our ongoing investments, we will complete our integrated production campus with a closed area of 17,000 square meters.

Here, we continue our investments with the vision of becoming one of the companies with the leading production capacity of the country in the Construction Machinery sector, where we have many years of experience. Currently, 95% of the products we produce are offered as OEM to the largest companies in the Construction Machinery sector in the European market. We also produce OEM assembled component products for the leading companies in the domestic construction machinery sector. Production starts with the combination of the molds created in our automatic resin sand molding line up to 1200x1000mm with the metal melted in 2×750 kg high efficiency and high frequency induction furnaces. In our fully automatic quenching furnace, which can reach temperatures of 1500kg - 1200 degrees, heat treatment is carried out according to the desired mechanical properties. The products, whose cleaning - purification processes are completed in our automatic sandblasting machine, are transferred to the machining department after the necessary mechanical and chemical analyzes are completed.

Current CNC machining machines, cutting, bending and specially designed equipment, different welding processes are used. With the motto that the quality of the unmeasurable product cannot be standardized, we have various dimension measurement devices and a precision CMM device suitable for today's technology in our laboratory, as well as Hardness devices, Surface hardness measurement device, Ultrasonic flaw detection device, Material analysis, tensile-compression test device and job-specific measurement equipment in our material laboratory. In our process management, we continue to work on ISO 9001 Quality Management System, ISO 14001 Environmental Management System, ISO 45001 Occupational Health and Safety Management System, which are the requirements of today. All processes are carried out in full compliance with the Enterprise Resource Planning software "Sysmond ERP". We maintain our production processes under full control with our Catia CAD-CAM and PLM software, which is a pioneer in its field. Using energy efficient equipment at every stage of production, Innometal aims to provide all of the energy it consumes from renewable energy with the awareness of respect for nature. In this context, with the solar energy facility, the 1st phase of which has been completed and commissioned, all of its current consumption is met from here. Human resources, which is one of the most important pillars of sustainable production, is one of the most valued aspects of our company. For this purpose, there are social areas within our campus to create a more decent working environment for our personnel. With the continuous trainings given to our employees, the working awareness and business knowledge of our personnel are increased.

To ensure that company personnel are aware of their individual OHS responsibilities by ensuring the consultation and participation of employees and employee representatives and to provide trainings for this purpose; To ensure continuous improvement of the OHS Management System; To ensure the elimination of occupational health and safety risks by taking measures in advance; To implement all necessary occupational safety measures to prevent accidents, damage to the health of employees and parties affected by the work, health deterioration, occupational diseases, environmental and social impacts; To comply with the legal legislation and administrative regulations regarding OHS in force; To periodically review the OHS Policy in order to maintain compliance with the conditions; To mutually share OHS experiences with public, private sector organizations and non-governmental organizations in order to ensure the continuous improvement of Occupational Health and Safety, Our company undertakes to ensure and maintain the above issues in order to protect the occupational health and safety of its employees and to continuously improve the working environment while carrying out its activities at the highest level of quality based on the principle of "Health and Safety First".

The management of our company, which aims to minimize the environmental impact of all our activities based on the principle of "Respect for Nature", will always be sensitive and careful about not harming the environment and will seek ways to protect natural resources. In order to continuously improve the environmental management system we have established and to prevent environmental pollution, it accepts and undertakes to provide training to all our employees, to ensure the continuity of training, to comply with the environmental legislation and administrative regulations in force, and to comply with other conditions to which it is automatically subject.